18 March, 2022

Branding Techniques For Glassware – Engraving

In our last blog, we discussed what you needed to look for when doing pad printing. Today we are going to talk about engraving. What the benefits are, what the negatives are and whether it is the right choice for your glassware.

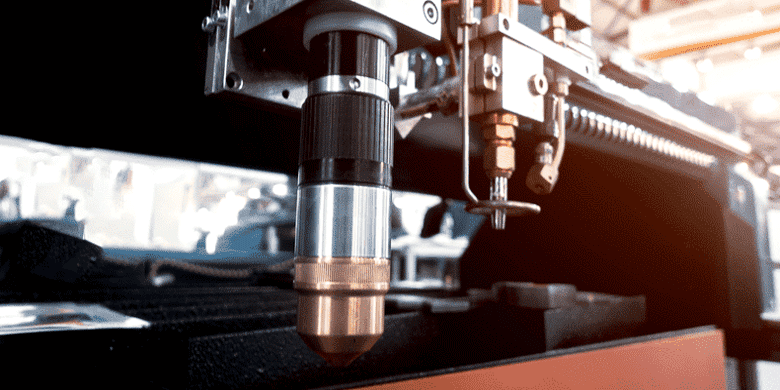

So, firstly, what is engraving and how does it work? Engraving is done by a laser tool. The laser is pointed to the glass and it removes minute bits of glass from the surface. As it does this, it creates a frosted appearance. As the laser moves along the glass, that small amount of frost gradually becomes the design that will eventually be on the glass. Just like printing, there are things to know before you decide to get engraved glassware.

1. Branding Size

2. Durability

3. Colours Required

4. Budget

Let’s go through all of these and hopefully it will help you decide what works best for what you want to achieve.

1. Branding Size: Most glassware has a curved surface. When engraving the glass is laid down. The laser comes from a direct line straight above. As the laser moves across the glass, when it curves, the laser can no longer make contact with the glass surface. This means there is a restrictive size of what we can brand. If you are engraving on a wine glass, the curve is not so severe, so you can get a larger area branded. On something skinnier, such as a champagne glass, the branding is very limited, usually to about 20mm width at best. Keep this in mind with what you want to put on the glass, as this will affect how much information you can add.

2. Durability: This is probably the most important part to consider and, in this case, engraving wins had down. Pad printing will eventually wear off your glassware, whereas engraving will last the lifetime of the glass until we dare say, it gets dropped and breaks. If you engrave, you can put your glass into the dishwasher without fear of it coming off. As the engraving is part of the glass and not something added on top, your logo or design will never be removed.

3. Colours Required: This is one part where engraving is extremely limited. There are no options in regard to colouring. The colour is a frosted look, as that is what happens when the top layer is removed from the glass. If you need colours for your logo, this branding process is not for you. What engraving does give you though is a very sophisticated look and makes the glass look premium? It is perfect for upmarket restaurants to put a small logo somewhere on the glass or as gifts to clientele.

4. Budget: Engraving fits right in-between pad printing and full-colour decals when it comes to costs. There is more handling involved than printing and you can only put several at a time into the laser engraving machine. There is a set-up cost as the machine needs to be calibrated for the size of the glass is engraved and that can sometimes take up to half an hour to do.

There are obvious benefits to engraving and hopefully the above will help you decide if it is the right option for your glassware. If you are unsure what would work best for your promotion, please don’t hesitate to contact us through email or a phone call and we’d love to assist.

The Glassware Only Team